How to switch to electrolyzed water?

Switching to electrolyzed water, specifically hypochlorous acid (HOCl), for sanitation involves a few key steps. Here’s a detailed guide on how to do it effectively, particularly for food processing environments:

1. Understand the Technology: HOCl, produced by electrolyzing a saltwater solution, is a powerful, non-toxic sanitizer that kills 99.99% of pathogens like Listeria and E. coli. It’s eco-friendly, breaking down into water and salt.

2. Choose Equipment: Install an EcoloxTech 240 or 1200 system to produce HOCl on-site, eliminating the need to buy and store traditional sanitizers.

3. Install and Use: These systems are wall-mounted and connected to water. HOCl can be used for surface cleaning, ice production, fogging, and staff sanitation without needing a post-rinse.

4. Benefits: HOCl reduces costs, water use, and labor. It’s eco-friendly and meets EPA, FDA, and USDA standards for food safety.

By switching to electrolyzed water, you can enhance food safety, reduce costs, and contribute to a sustainable operation. EcoloxTech's systems make this transition smooth and highly beneficial for food processors.

EcoloxTech is the World's Leading Manufacturer

of Hypochlorous Acid Generators & Solutions

Benefits of Utilizing HOCl in Various Industries

Here’s how different industries can leverage hypochlorous acid (HOCl) to

enhance safety, efficiency, and product quality:

1. Sanitizing Surfaces and Products

HOCl is highly effective at eliminating dangerous pathogens such as Listeria, E. coli, and Salmonella. It can be applied directly to surfaces and products without leaving harmful residues, making it ideal for maintaining a safe, contamination-free environment in various sectors, including food processing and healthcare.

2. Extending Product Shelf Life

Research shows HOCl significantly extends the shelf life of products by reducing spoilage without altering their taste, smell, or quality. This helps industries reduce waste and improve profitability.

3. Enhancing Staff Hygiene

HOCl is gentle on the skin, making it safe for frequent hand washing and equipment sanitation. It helps maintain high hygiene standards in facilities without the harsh effects of traditional chemical disinfectants, reducing the risk of cross-contamination.

4. Ice Production

In various industries, ice plays a crucial role in storing and transporting products. HOCl can be incorporated into ice production systems, ensuring that the ice remains pathogen-free. This helps maintain product safety and quality during storage and transport, preventing contamination throughout the supply chain.

5. Sanitizing Water Systems

HOCl can be integrated into water systems for cooling or storage, ensuring that water or ice used in various industries remains pathogen-free, maintaining product safety throughout the supply chain.

6. Surface and Equipment Sanitation

HOCl can sanitize a wide range of surfaces, from countertops to machinery, ensuring a clean and safe operational environment. Its non-corrosive nature extends the life of equipment, making it suitable for industries like manufacturing, hospitality, and food processing.

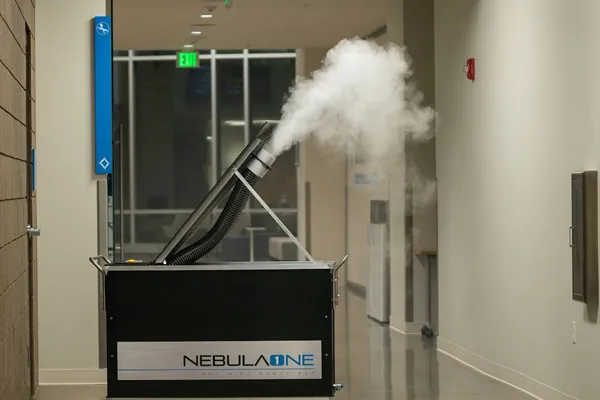

7. Air and Facility Sanitation

HOCl can be used in fogging systems to sanitize air and hard-to-reach areas within facilities, creating a safer environment for both products and employees across industries.

8. Wound Care for Staff

In case of minor injuries, HOCl can be used as an antimicrobial wound care solution, preventing infections and promoting faster healing without irritation, enhancing employee safety in workplaces like healthcare or industrial settings.

9. Neutralizing Odors

HOCl effectively neutralizes strong odors, improving the working environment in industries that face challenges with unpleasant smells, such as waste management or food processing.

10. Environmental Sustainability

As a biodegradable and eco-friendly solution, HOCl breaks down into saltwater, reducing environmental impact compared to traditional chemical sanitizers.

11. Onsite Production

HOCl can be produced onsite using electrolysis, eliminating the need to store and transport large quantities of chemical sanitizers. This reduces costs, enhances safety, and ensures a continuous supply of fresh disinfectant.

12. Cost-Effectiveness

Producing HOCl onsite is more cost-efficient than managing traditional chemical sanitizers. It lowers labor, shipping, and storage expenses while improving the overall efficiency of sanitation processes.

13. Effectiveness Against Product Deterioration

HOCl has been proven effective in preventing quality degradation, such as melanosis (black spots) in seafood. This helps preserve the visual appeal and marketability of products, benefiting industries where appearance is critical, such as food and retail sectors.

EcoloxTech is the World's Leading Manufacturer of HypoChlorous Acid Generators & Solutions

EcoloxTech is a pioneering, woman-owned business dedicated to advancing sustainable environmental solutions. Our core mission is to innovate and deliver eco-friendly technologies that contribute to global sustainability efforts, emphasizing the importance of reducing carbon footprints and promoting green practices across industries. Our range of products and services includes cutting-edge water purification systems, eco-friendly disinfection solutions, and bespoke sustainability consulting designed to meet the unique needs of our clients.